hkyrollformingmachine

Special Order Floor Deck Roll Forming Machine

Special Order Floor Deck Roll Forming Machine

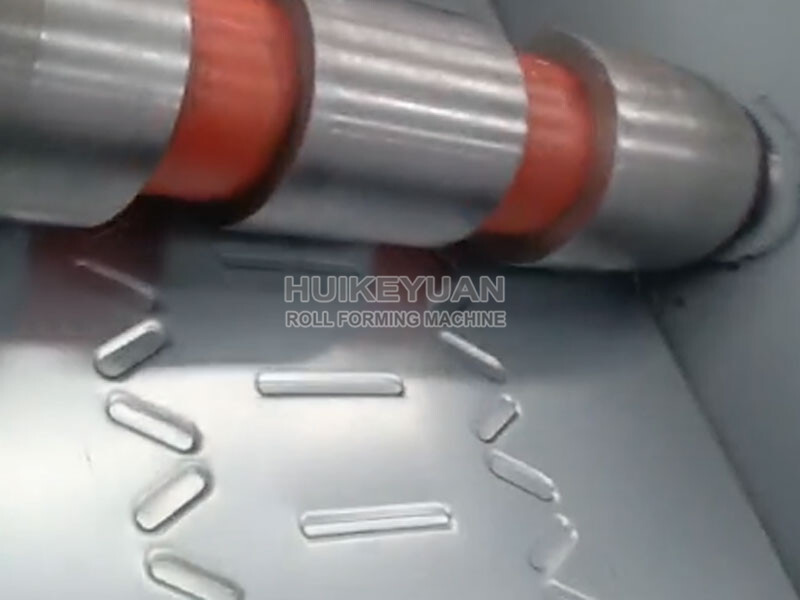

Floor Deck Roll Forming Machine is galvanized steel as a raw material, after rolling cold-formed technology, die forming, mainly used for the production of steel works with floor boards, rolled into the floor boards after its V-shaped cross-section into categories, U-type, a ladder or a combination of several shapes, mainly used to make permanent formwork composite slab or concrete slab.

technical parameter

Process flow: hydraulic automatic uncoiler → leveling → embossing → forming machine → reshaping → punching → hydraulic die cutting → discharging 1. Hydraulic uncoiler 2. Size of formed profile: 400 / 91mm a. Production speed: 10-15m / min b. Thickness range is 2.0 ± 0.5mm 3. Leveling machine a. Number of working rollers: 5-roller leveler 4. Molding host a. Motor power of forming machine: 2x11 = 22kw b. Roller stations: 20 rows c. Production speed: 10-15m / min d. Roll material: Cr12, quenching hardness HRC58-62 e. Form of forming machine: the whole plate of side plate is accurately positioned with boring bearing, f. 2.5 inch chain drive g. Diameter of main shaft: ¢ 120mm 5. Cutting off a. Form: Die Cutting 6. Electrical control system: a. The whole line PLC control, LCD touch screen, human-machine interface b. There are two operation modes: manual and automatic |

- Type:

- Tile Forming Machine

- Production Capacity:

- min. 20 m/min

- Power(W):

- 3-15 KW

- Certification:

- CE,ISO,SGS,BV

- Condition:

- New

- Tile Type:

- Steel

- Use:

- Roof

- Place of Origin:

- Hebei, China

- Brand Name:

- HKY

- Voltage:

- 380V,50Hz,3Phase

- Dimension(L*W*H):

- 7.5m*1.5m*1.2m

- Weight:

- 3 - 6 T

- Profile:

- Color Steel Tile

- Product Max Effective Width:

- 640-1120 mm

- Max Feeding Width:

- 1000-1250 mm

- Thickness of Material:

- 0.1mm-1.5mm

- Rollers Station:

- 95mm Main Shaft &Standard 14 Rows

- Electrical System:

- PLC and HMI touch Screen

- Cutting System:

- Hydraulic Cutting & Four Pole Structure

- Machine Body:

- Electrostatic Spraying Treatment

- Method:

- Cold Press Roll Forming

- Feeding Material:

- GI sheet coil or cold rolled coil etc.

- After-sales Service Provided:

- Engineers available to service machinery overseas

- Warranty:

- 1 Years

xxxxxx

- Home

- New products

-

All Products

- Roof sheet roll forming machine

- Double/Three Layer Forming Machine

- Glazed Tile Roll Forming Machine

- C/Z/U Purlin Roll Forming Machine

- Floor Deck/Angle Jch Roll Forming Machine

- Light Steel Keel Roll Forming Machine

- Light Keel Villa House Roll Forming Machine

- Shutter Door and Door Frame Roll Forming Machine

- Roofing Ridge Cap Making Machine

- EPS Sandwich Panel Roll Forming Machine

- Cable Tray Roll Forming Machine

- Highway Guardrail roll forming machine

- Storage Shelves Roll Forming Machine

- Car Carriage Plate Roll Forming Machine

- 3d Wall Panel Roll Forming Machine

- Curving/Arch Roll Forming Machine

- Leveling shearing slitting machine

- Shearing & Bending machine

- Decoiler

- Industry Products

- Video

- Blog

- Contact

Your cart is currently empty.

USD

USD