hkyrollformingmachine

Z Lock EPS and Rock Wool Sandwich Panel Production Line

Z Lock EPS and Rock Wool Sandwich Panel Production Line

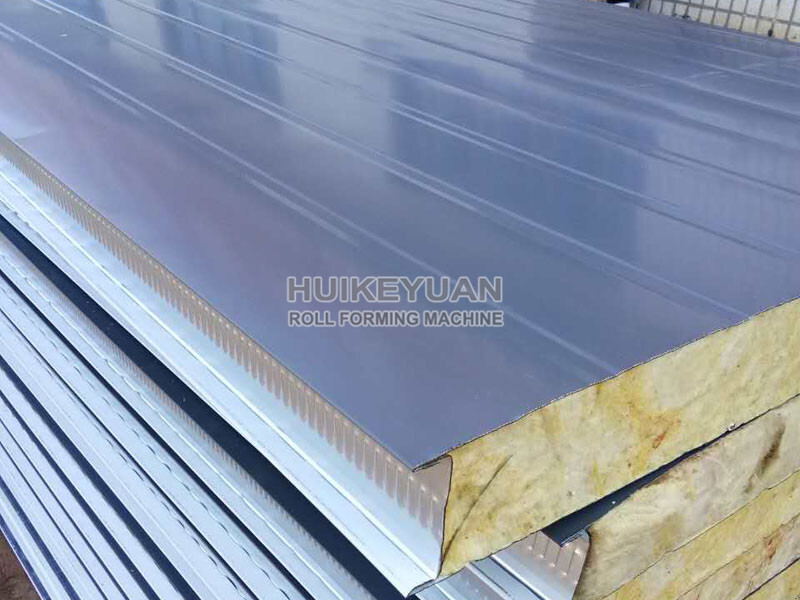

Z Lock EPS and Rock Wool Sandwich Panel Machine Production Line is the best machine which can produce the color steel and EPS or rock wool composite board, which is also named sandwich panel machine. It is special machinery equipment using the pneumatic, electric and mechanical as a whole to produce the color steel heat preservation, sandwich panel.

The working speed uses the frequency conversion stepless speed regulation, and can composite the corrugated sandwich panel one-time.

The fully automatic sandwich panel roll forming machine use the full automatic control system with high integrated network, to achieve production information management, so as to make the automation system more advantageous, with the operation, maintenance, maintenance and mechanical debugging, and so on.

1 Main moter power: 32KW

2 out line dimension of machine: 33m*2.5m*2.5m

3 Total weight: 10T

4 Processing speed: 0-5m/min

5 the thickness of upper steell plate: 0.3-0.8mm

6 the feeding width of upper steel plate: 1000/1200/1250mm

7 the thickness of lower steel plate: 0.3-0.8mm

8 the feeding width of lower steel plate: 1000/1200/1250mm

9 sandwich material: EPS/rock wool/PU/glass wool/foam

10 the thickness: 38-298mm

11 the width of stocket board: 950/1150mm

12 the width of H board: 1000/1200mm

13 the whole sandwich panel lien includes load car, up roll forming machine, down roll forming machine,roof corrugated roll forming imachine, roller unit,heat unit, glue nunit,double belt machine, saw belt cutter unit and production table

14. Material of main equipment:

(1)Roll material:high grade NO.45 forged steel,plate hard chrome on the surface of roller with thickness 0.05mm.

(2)Active shaft material:high grade No.45 carbon wrought steel at diameter 75mm

(3)Cutter blade:Cr12 mould steel with quenched treatment

(4)Producing flow:

Decoiling the sheet-sheet guiding-roll forming-measure length-cutting the panel-panels to the supporter

- Applicable Industries:

- Construction works

- After Warranty Service:

- Video technical support, No service, Online support, Spare parts, Field maintenance and repair service

- Local Service Location:

- None

- Showroom Location:

- None

- Condition:

- New

- Type:

- Tile Forming Machine

- Tile Type:

- Colored Steel

- Use:

- Wall

- Place of Origin:

- Hebei, China

- Brand Name:

- HKY

- Voltage:

- 380V, 50Hz

- Weight:

- 5T

- Certification:

- CE/ISO

- Warranty:

- 1 YEAR, 12 months

- Key Selling Points:

- Easy to Operate

- After-sales Service Provided:

- Engineers available to service machinery overseas

- main moter power:

- 32kw

- Raw Material:

- Aluminium/Color Steel/Galvanized Sheet

- Automaticity:

- PLC comtrol system

- certificate:

- CE

- material of roller:

- 45#steel hard chrom plating

- sprocket:

- P-25.4

- speed:

- 8-12m

- Production Capacity:

- 8-12m/min

xxxxxx

- Home

- New products

-

All Products

- Roof sheet roll forming machine

- Double/Three Layer Forming Machine

- Glazed Tile Roll Forming Machine

- C/Z/U Purlin Roll Forming Machine

- Floor Deck/Angle Jch Roll Forming Machine

- Light Steel Keel Roll Forming Machine

- Light Keel Villa House Roll Forming Machine

- Shutter Door and Door Frame Roll Forming Machine

- Roofing Ridge Cap Making Machine

- EPS Sandwich Panel Roll Forming Machine

- Cable Tray Roll Forming Machine

- Highway Guardrail roll forming machine

- Storage Shelves Roll Forming Machine

- Car Carriage Plate Roll Forming Machine

- 3d Wall Panel Roll Forming Machine

- Curving/Arch Roll Forming Machine

- Leveling shearing slitting machine

- Shearing & Bending machine

- Decoiler

- Industry Products

- Video

- Blog

- Contact

Your cart is currently empty.

USD

USD